The goal of Live Lab 3 is to demonstrate how data analysis and advanced control techniques can optimize the control for the process industry.

This Live Lab is situated in POLITO’s facility in Turin, Italy and in TU Dublin’s laboratory in Ireland. The Live Lab focuses on control room operations and human situational awareness during stressful interventions i.e., alarms. Primarily this Live Lab will be based on Yokogawa’s facility with a particular focus on risk monitoring in control runs. To facilitate the research, Yokogawa are providing a dataset with over 150,000 samples and 44 features, consisting of timestamps of alarm and alert events.

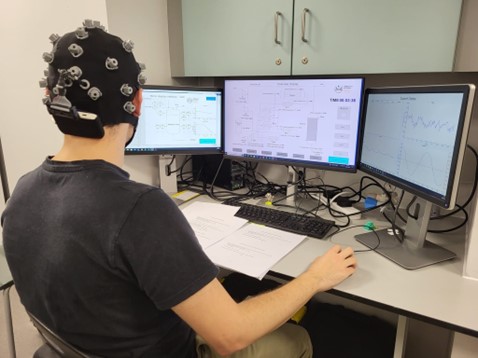

The Live Lab will also provide a simulated Distributed Control System (DCS) in a laboratory setting. The system can accurately simulate a process plant and has the flexibility to allow different scenarios of normal operations, failures, and emergencies to be simulated through a scenario editor. The simulator is customizable to produce a range of scenarios and fit with different possible Human Machine Interface (HMI) and DCS environments.

This empirical study aims to investigate the influence of both obvious and latent factors (human, organization, and technical) during man-machine interaction and the consequence on human performance and safety. A case study on the production of formaldehyde in a chemical plant has been selected and simulated for this purpose. The facility produces around 10000 kg/h of 30% formaldehyde solution, operating the partial oxidation of methanol with air. The human-in-the-loop configurations in the simulation are varied from monitoring to both monitoring and control. Both normal and abnormal situations have been considered as well.